- Offering solutions to increase compressor run-time & reliability.

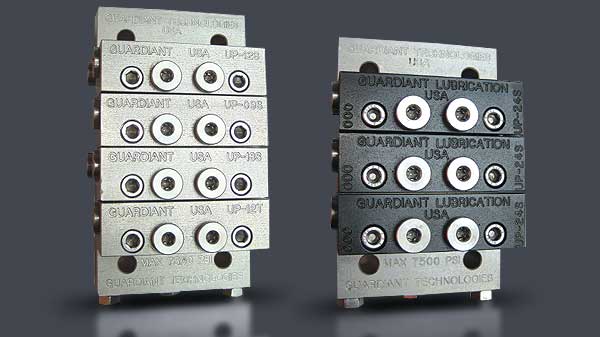

- 80-90 millionths piston-to-bore tolerance.

- Assures accurate delivery of oil in thousandths of a cubic inch-to-cylinder and packing lubrication points.

- Available in a wide variety of sizes – .006, .009, .012, .015, .018, .021, .024, and .030.

- Come in both “S” (single) and “T” (twin) outputs.

- Direct replacements for most major divider block manufacturers.

What we offer

Here we show some of our most important products

Divider Blocks - Carbon Steel & Stainless Steel

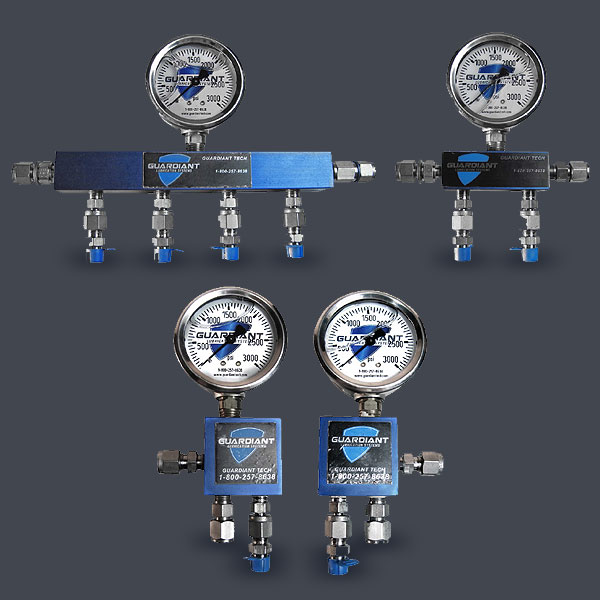

LOW PRESSURE GLS DELTA-P FILTER ASSEMBLY

- 10 PSI differential pressure between gauges indicates “time to replace filter element”

- B118 “spin-on / non-bypass” replacement filter element (12 micron)

- Filters the oil supply prior to entering the lube pump and protects the pumping element

- Extends the life of the lubrication pump

GLS - S.S. High Pressure Filter Assembly

- Filters oil supply prior to entering the divider block to reduce wear on the metering element

- Elements available in 10 and 25 microns

GLS Manual Oil Purge Gun

- The Guardiant manual oil purge gun is one of the most important tools a mechanic/operator should have for:

- preventive maintenance

- pressure testing

- purging a lube system

- checking bent, leaking, or plugged tubing, prior to compressor start-up

- Purge gun comes with an outlet check valve, 5000 PSI gauge and 36” braided stainless steel, high pressure hose with tubing fitting connector to adapt to the divider block inlet fitting

- The new GLS purge gun design eliminates breaking or kinking of the stainless steel whip

Pneumatic Purge Pump Assembly

- 1.5 gallon oil tank capacity

- 5,000 PSI working pressure

- High pressure isolation valve for testing divider valves and check valves

- Requires a 60 PSI air supply to achieve test pressure

- Includes a long high pressure hose for ease of mobility when climbing around the compressor and power cylinders

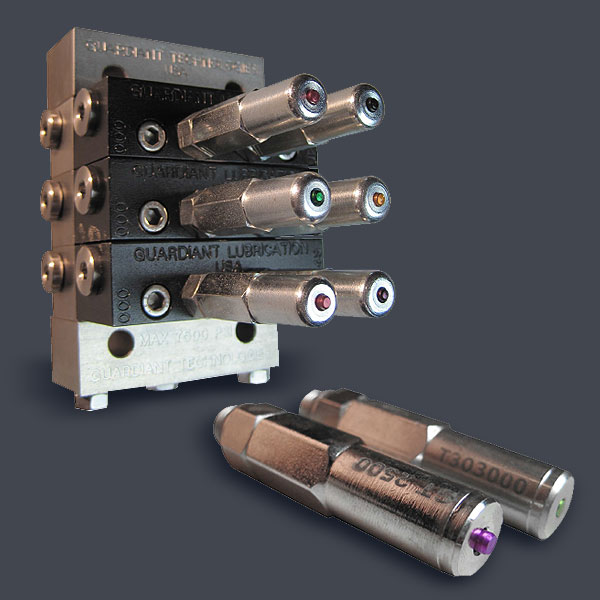

Injection Check Valves

- Injection S. S. check valves with integrated tube fitting and lube point primer.

Suction Manifold Assemblies

- 4 pump suction manifold

- 2 pump suction manifold

Discharge Manifold Assemblies

- 4 pump discharge manifold

- 2 pump discharge manifold

- Left & right 1-pump manifold

HVLP Discharge Manifold

Rupture to Atmosphere Blow-Out Assemblies and Replacement Rupture Discs

- Vivid colors make identification quick & easy

- Available for 2000 and 3250 PSI, and additional PSI measurements

Memory Reset Pin Indicator

- Pin Indicator gives a visual indication (road map) to show there is a problem with a specific lubrication point

- Helps operator/mechanic find blocked point, solve problem and get compressor back online

- Mechanic will need to manually pressure-up the system to locate the problem if pin indicators are not used. Checking each lubrication point can be time consuming and delay placing compressor back online.

- Vivid colors make identification quick and easy

- Available from 1500 to 5000 PSI, with additional PSI measurements in-between

Balance Valve Assemblies

- Divider blocks are hydraulic systems that must be balanced to prevent fluid hammering, which can cause premature wear of pistons, pumps, lubricator box components and phantom rupture disc failure

- Balancing Vales - Are required when your differential pressures are over 1000 PSI.

- Balancing valve assemblies prevent:

- premature wear and failure of divider blocks

- blown rupture disc problems due to divider block pistons bouncing (slapping) out-of-sync

- excessive differential pressure in the system eliminating piston by-passing

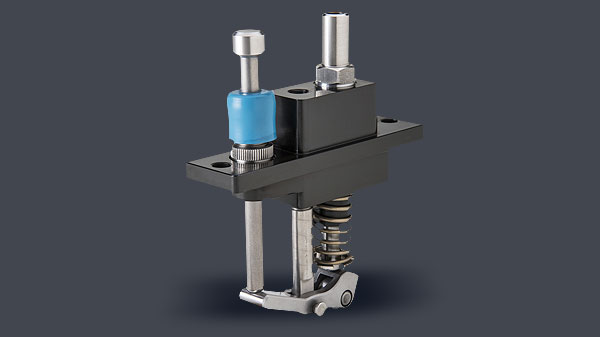

Model 55 Style Lubricator Pumps

- Box Suction & Pressure Fed Style Pump’s.

- Roller Rocker Arm.

- Armored Sight Glass.

- 1/4” - 3/8” Piston Sizes.

Our Distributors

Here it is the list of Companies that already trust us.

Our Distributors

Here you will access the list of companies that already trust in our products and services, and together we grow strongly.

Training Photos & Videos

In this Section you will find our latest training photos and videos.

Contact us

Doubts? Questions? Feel free to Send Us an Email

Get in touch

HeadQuarters

Address:

8525 Jack Rabbit Rd. Unit A

Houston, Texas 77095

Houston, Texas 77095

Phone:

+1 (800) 257-8638 Toll Free

Email: